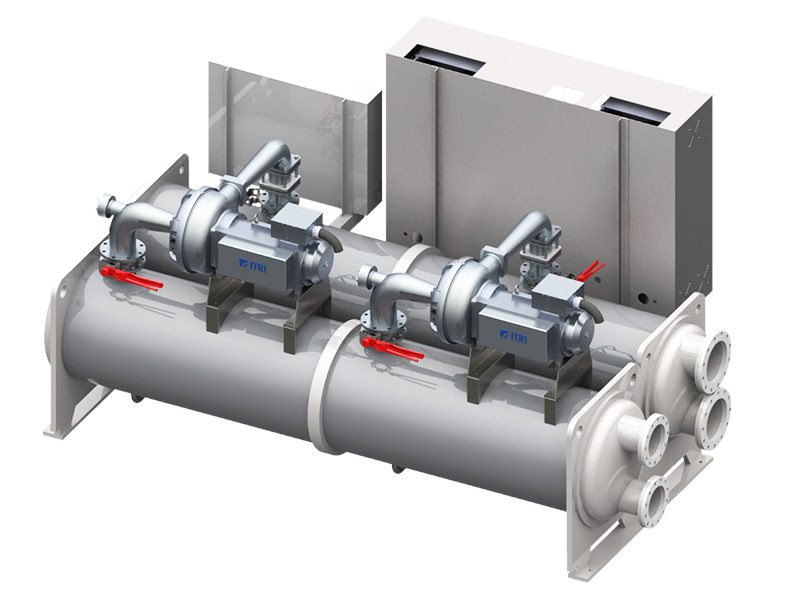

ACTIVE MAGNETIC BEARING CHILLER

Active Magnetic Bearing Chiller

- The Active Magnetic Bearing Chiller's (180tons - 500tons) maximum efficiency is up to COP 7.2 / IPLV 12

- Using R-134a refrigerant without lubricant can solve the problem of heat exchanger attenuation and reduce maintenance costs.

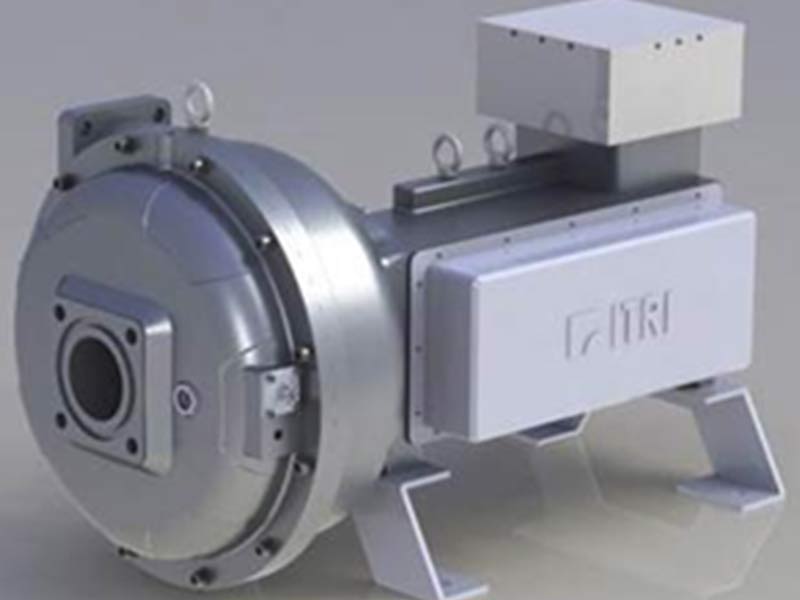

LEADING cooperated with ITRI (Industrial Technology Research Institute) to develop a variable frequency Active Magnetic Bearing Chiller, which uses magnetic force control to stably suspend the rotor so the spindle does not contact with the bearing and does not require lubricant to achieve a high speed and friction-free effect; and with the smart controller, the surge early warning suppression technology is carried out to improve the system reliability. Compared with the traditional screw chiller, the magnetic levitation centrifugal chiller is greatly reduced in volume and weight, the operating noise is also less than 75 decibels, and the power saving is about 30 - 40% throughout the year.